All employees should be trained on how to handle hazardous materials safely, especially those that they will personally be using on a regular basis.

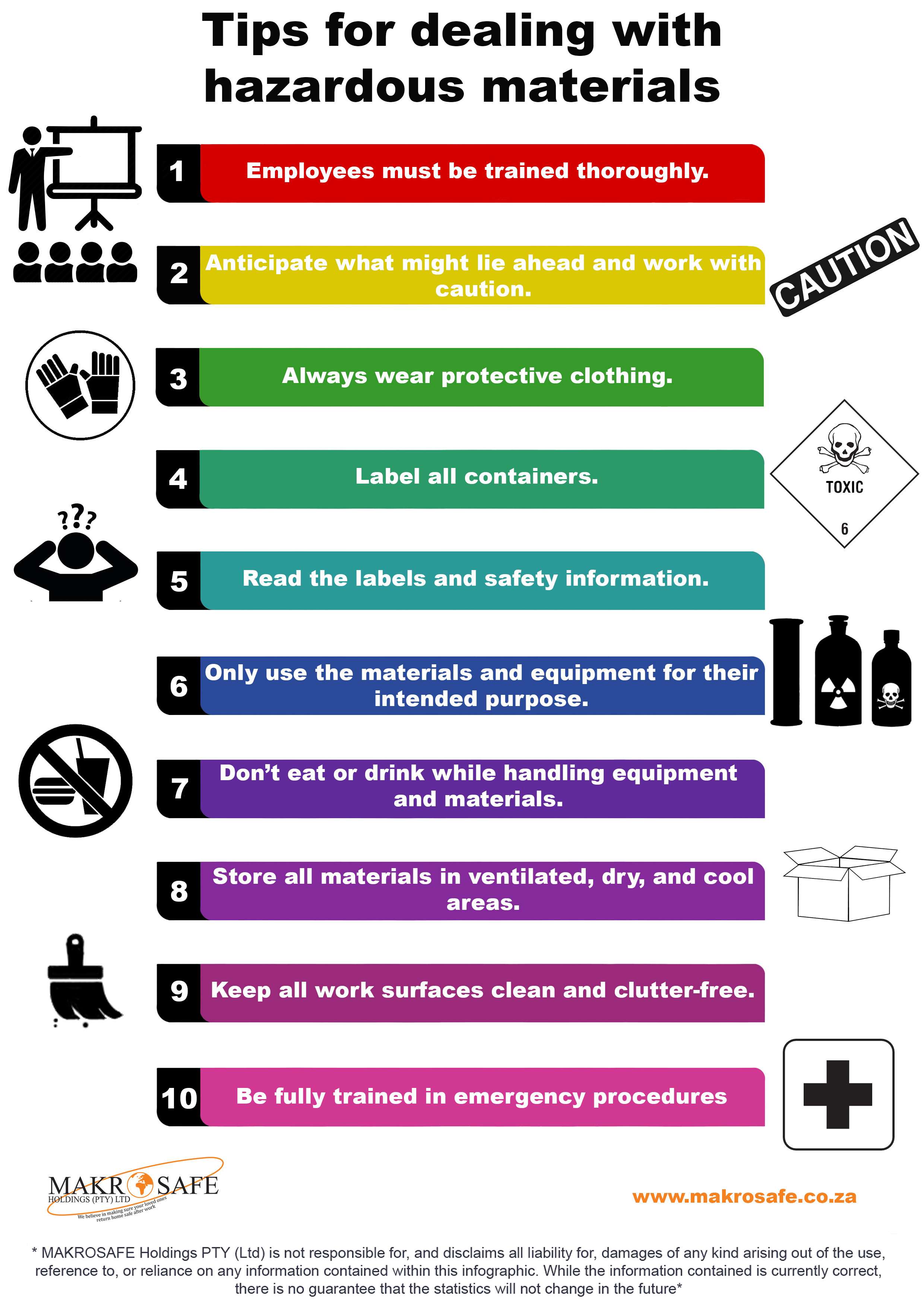

The following tips apply to handling of most hazardous materials:

- Formal procedures must be in writing and employees trained thoroughly.

- Be proactive. Anticipate what might lie ahead and work with caution. For example, be aware of slippery surfaces when it has just rained.

- Always wear protective clothing and inspect each item before putting it on.

- Label all containers and make sure chemicals are stored appropriately.

- Read the labels and safety information on all hazardous material before using them.

- Only use the materials and equipment for their intended purpose. For example, don’t use petrol to wipe down equipment (a common trick mechanics use).

- Don’t eat or drink while handling equipment and materials.

- Store all materials in ventilated, dry, and cool areas. Make sure that potentially incompatible hazards are stored separately.

- Keep all work surfaces clean and clutter-free.

- Be fully trained in emergency procedures (for example, evacuations) and how to use emergency equipment (such as a fire hydrant).

Posted date: 12th Feb 2018

Latest News - Security Industry - Educational Services Industry - Food Drinks and Tobacco Industry - Wood and Upholstery Industry - Printing and Paper Industry - Chemical Rubber Oil and Paint Industry - Iron Steel Artificial Limbs Galvanizing Garages and Metals Industry - Trade and Commerce Industry - Banking and Insurance Industry - Airline Aviation Industry - Road Transport Hauliers Industry - Entertainment and Sport Industry - Professional Services Hospitality Industry - Charitable Religion Political and Trade Organisations Industry - Glass Brick Tiles and Concrete Industry

Leave a comment