How to minimize worker exposure to hazards in the workplace

Job rotation is the structured interchange of workers between different jobs, requiring workers to rotate between different workstations or jobs at certain time intervals.

Job Rotation

Job rotation increases the variety of tasks required as the worker takes on more duties, enlarging the physical demands and adding variety to the job.

The objective is to provide a consistent and systematic method of developing formal job rotations that are based on the requirements of the job being rotated.

It’s important to remember that job rotation doesn’t eliminate ergonomic risk factors. While job rotation is an effective control measure for jobs that have been identified as “problem” or “high-risk” jobs, it is desirable that ergonomic risk factors are “hidden” by administrative controls.

Obviously, ergonomic problems should be addressed and fixed whenever possible. With the above “caution” being stated, it’s equally important to recognise the many great benefits to implementing job rotation in the workplace.

Benefits of Job Rotation

Many studies have identified a variety of benefits from implementing job rotation including:

Reduced exposure to focused physical demands for one job.

Reduced physiological stress, strain, and fatigue to muscle group used for one job.

Reduces employee exposure to high-risk job demands.

Reduced MSD incidents and severity.

Increased innovation and improved work process efficiently.

Improves employee skill base and increases job assignment flexibility over time.

Reduced boredom and complacency.

Increased productivity and quality.

Reduced absenteeism and turnover.

Potential Barriers to Job Rotation

There are several potential barriers and difficulties with implementing job rotation, the following are some of them:

Not all jobs and departments are a good fit for job rotation.

Short-term productivity losses and product quality issues.

Workers not wanting to rotate because they have an “ easier job”.

Workers not wanting to change jobs to learn new work tasks for a variety of reasons.

Workers not wanting to give up “their job” to others.

Workers not qualified for some jobs due to restrictions or abilities.

Union or other workplace policies related to job bidding and compensation.

Supervisors are not convinced that the benefits are worth the perceived costs.

Supervisors perceive that implementation and management of job rotation is very difficult.

Group leaders and trainers tend to focus on the short-term costs rather than the long-term benefits, and perceive that the costs are too high for them verses the benefits.

Supervisors and group leaders not wanting to “fight” employees who don’t want to rotate.

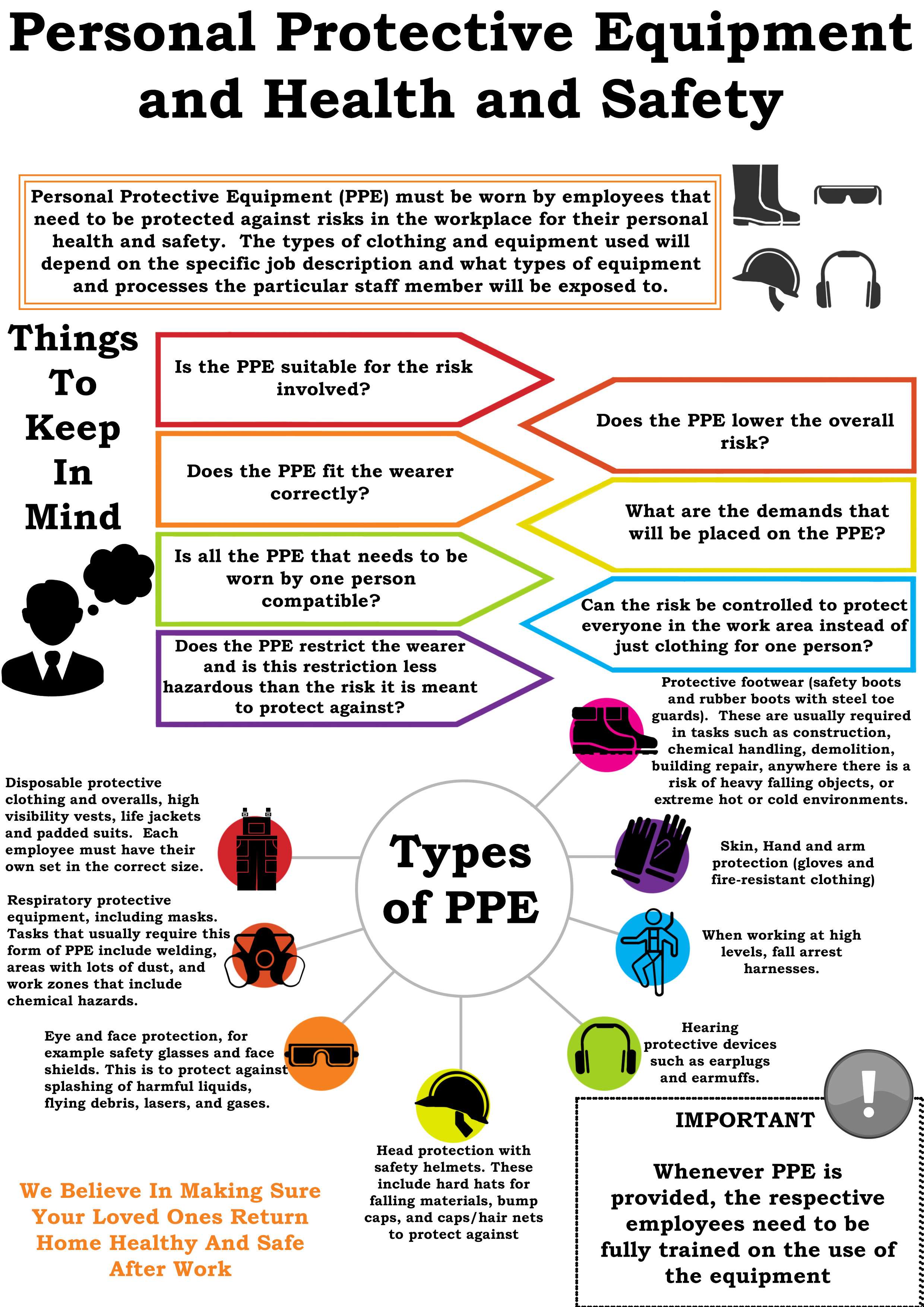

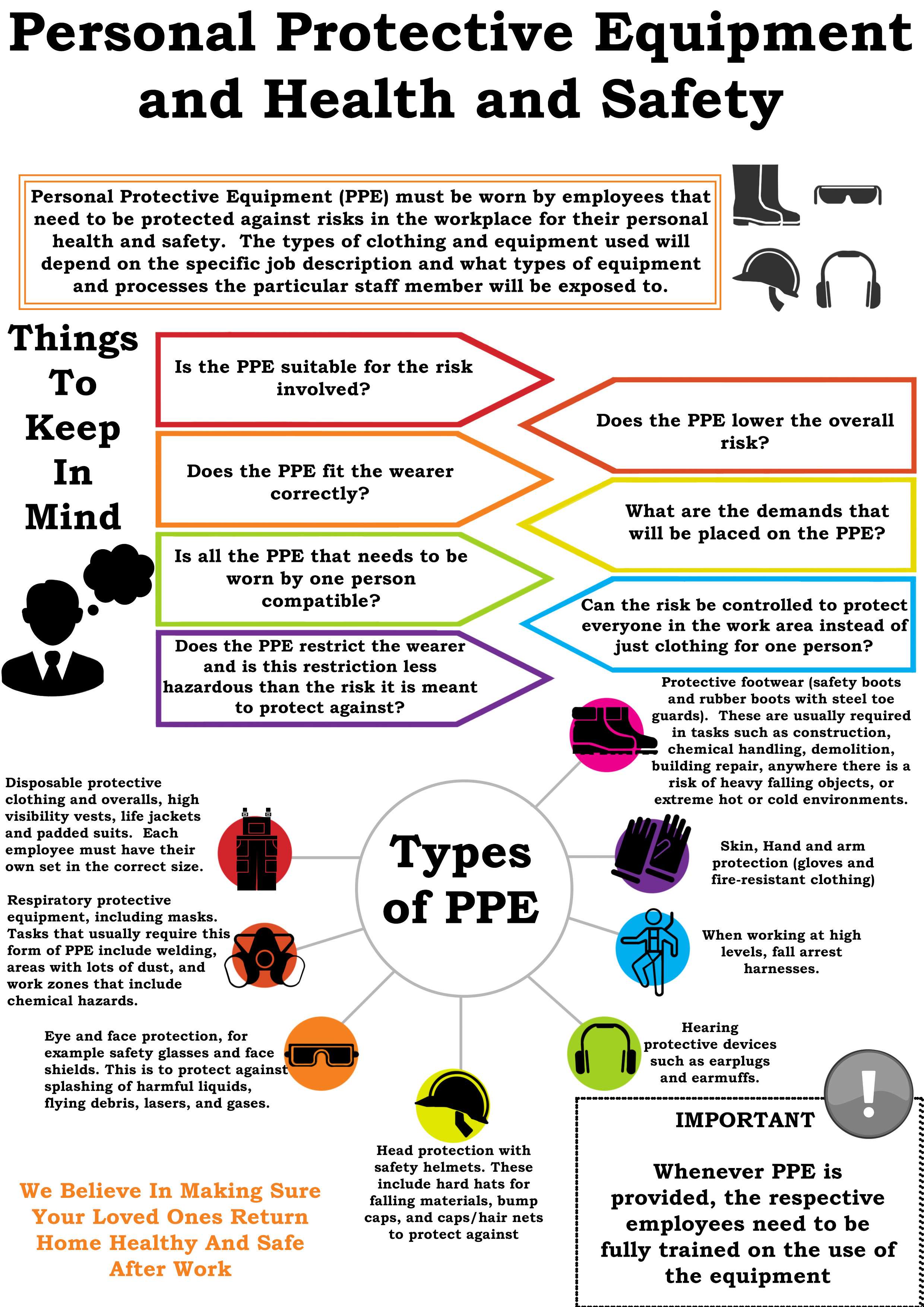

PPE

Employers have duties concerning the provision and use of personal protective equipment (PPE) at work.

Health and Safety Risk Assessment

PPE will be identified as a Control Measure in the Risk Assessment and is Task Based.

Equipment

PPE is equipment that will protect the user against health or safety risks at work. It can include items such as:

Safety helmets

Gloves

Eye protection

High-visibility clothing

Safety footwear and safety harnesses

It also includes respiratory protective equipment (RPE).

Why is PPE important?

Making the workplace safe includes providing instructions, procedures, training and supervision to encourage people to work safely and responsibly. Even where engineering controls and safe systems of work have been applied, some hazards might remain. These include injuries to:

The lungs from breathing in contaminated air

The head and feet, for example from falling materials

The eyes, for example from flying particles or splashes of corrosive liquids

The skin, for example from contact with corrosive materials

The body, for example from extremes of heat or cold

PPE is needed in these cases to reduce the risk.

What do I have to do?

Only use PPE as a last resort

If PPE is still needed after implementing other controls, and there will be circumstances when it is, for example head protection on most construction sites, you must provide this for your employees free of charge.

You must choose the equipment carefully, see selection details below, and ensure employees are trained to use it properly, and know how to detect and report any faults.

Selection and use

You should ask yourself the following questions:

Who is exposed and to what?

How long are they exposed for?

How much are they exposed to?

When selecting and using PPE:

Choose products which are SABS marked in accordance with the Personal Protective Equipment Regulations - suppliers can advise you.

Choose equipment that suits the user - consider the size, fit and weight of the PPE. If the users help choose it, they will be more likely to use it.

If more than one item of PPE is worn at the same time, make sure they can be used together, for instance, wearing safety glasses may disturb the seal of a respirator, causing air leaks.

Instruct and train people how to use it, for example train people to remove gloves without contaminating their skin. Tell them why it is needed, when to use it and what its limitations are.

Nevel allow exemptions from wearing PPE for those jobs that only take a few minutes.

Check with your supplier on what PPE is appropriate - explain the job to them.

If in doubt, seek further advice from a specialist adviser.

Maintenance

PPE must be properly looked after and stored when not in use, for instance, in a dry, clean cupboard. If it is reusable it must be cleaned and kept in good condition.

Think about rules:

Using the right replacement parts which match the original, for example respirator filters.

Keeping replacement PPE available.

Who is responsible for maintenance and how it is to be done.

Having a supply of appropriate disposable suits which are useful for dirty jobs where laundry costs are high, for example for visitors who need protective clothing.

Employees must make proper use of PPE and report its loss or destruction or any fault in it.

Monitor and review

Check regularly that PPE is used. If it isn’t, find out why not.

Safety signs can be a useful reminder the PPE should be worn.

Take note of any changes in equipment, materials and methods - you may need to update what you provide.

Types of PPE you can use:

Body Part: Eyes

Hazard: Chemical or metal splash, dust, projectiles, gas and vapour, radiation

Options: Safety spectacles, goggles, face screens, face shields, visors

Make sure the eye protection chosen the right combination of impact, t/splash/molten/metal eye protection for the task and fits the user properly.

Body Part: Head and neck

Hazard: Impact from falling or flying objects, risk of head bumping, hair getting tangled in machinery, chemical drips or splash, climate or temperature

Options: Industrial safety helmets, bump caps, hairnets and firefighters’ helmets

Some safety helmets incorporate or can be fitted with specially-designed eye or hearing protection. Don’t forget neck protection, for example scarves for use during welding. Replace head protection if it is damaged.

Body Part: Ears

Hazard: Noise - a combination of sound level and duration of exposure, very high level sounds are a hazard even with short duration.

Options: Earplugs, earmuffs, semi insert / canal caps

Provide the right hearing protectors for the type of work, and make sure workers know how to fit them. Choose protectors that reduce noise to an acceptable level, while allowing for safety and communication.

Body Part: Hands and arms

Hazard: Abrasion, temperature extremes, cuts and punctures, impact, chemicals, electric shock, radiation, vibration, biological agents and prolonged immersion in water.

Options: Gloves, gloves with a cuff, gauntlets and sleeving that covers part or all of the arm

Avoid gloves when operating machines such as bench drills where the gloves might get caught. Some materials are quickly penetrated by chemicals, take care in selection. Barrier creams are unreliable and are no substitute for proper PPE. Wearing gloves for long periods can make the skin hot and sweaty, leading to skin problems. Using separate cotton inner gloves can help prevent this.

Body Part: Feet and legs

Hazard: Wet, hot and cold conditions, electrostatic build-up, slipping, cuts and punctures, falling objects, heavy loads, metal and chemical splash, vehicles.

Options: Safety boots and shoes with protective toe caps and penetration-resistant, mid-sole wellington boots and specific footwear, e.g. foundry shoes and chainsaw boots.

Footwear can have a variety of sole patterns and materials to help prevent slips in different conditions, including oil - or chemical-resistant soles. It can also be anti-static electrically conductive or thermally insulating. Appropriate footwear should be selected for the risks identified.

Body Part: Lungs

Hazard: Oxygen-deficient atmospheres, dust, gases and vapours

Option: Respiratory protective equipment (RPE). Some respirators rely on filtering contaminants from workplace air. These include simple filtering facepieces and respirators and power-assisted respirators. Make sure it fits properly, e.g. for tight-fitting respirators (filtering facepieces, half and full masks). There are also types of breathing apparatus which gives an independent supply of breathable air, e.g. fresh-air hose, compressed airline and self-contained breathing apparatus.

Filters have only a limited life. Where there is a shortage of oxygen or any danger of losing consciousness due to exposure to high levels of harmful fumes, only use breathing apparatus, never use a filtering cartridge. You will need to use breathing apparatus in a confined space or if there is a chance of an oxygen deficiency in the work area.

Body Part: Whole body

Hazard: Heat, chemical or metal splash, spray from pressure leaks or spray guns, contaminated dust, impact or penetration, excessive wear or entanglement of own clothing.

Options: Conventional or disposable overalls, boiler suits, aprons, chemical suits.

The choice of materials includes flame-retardant, anti-static, chain mail, chemically impermeable, and high-visibility. Don’t forget other protection , like safety harnesses or life jackets and emergency equipment. Careful selection, maintenance and realistic operator training is needed for equipment for use in emergencies, like compressed-air escape breathing apparatus, respirators and safety ropes or harnesses.

For all your Health and Safety needs, click on the picture below:

Job rotation is the structured interchange of workers between different jobs, requiring workers to rotate between different workstations or jobs at certain time intervals.

Job Rotation

Job rotation increases the variety of tasks required as the worker takes on more duties, enlarging the physical demands and adding variety to the job.

The objective is to provide a consistent and systematic method of developing formal job rotations that are based on the requirements of the job being rotated.

It’s important to remember that job rotation doesn’t eliminate ergonomic risk factors. While job rotation is an effective control measure for jobs that have been identified as “problem” or “high-risk” jobs, it is desirable that ergonomic risk factors are “hidden” by administrative controls.

Obviously, ergonomic problems should be addressed and fixed whenever possible. With the above “caution” being stated, it’s equally important to recognise the many great benefits to implementing job rotation in the workplace.

Benefits of Job Rotation

Many studies have identified a variety of benefits from implementing job rotation including:

Reduced exposure to focused physical demands for one job.

Reduced physiological stress, strain, and fatigue to muscle group used for one job.

Reduces employee exposure to high-risk job demands.

Reduced MSD incidents and severity.

Increased innovation and improved work process efficiently.

Improves employee skill base and increases job assignment flexibility over time.

Reduced boredom and complacency.

Increased productivity and quality.

Reduced absenteeism and turnover.

Potential Barriers to Job Rotation

There are several potential barriers and difficulties with implementing job rotation, the following are some of them:

Not all jobs and departments are a good fit for job rotation.

Short-term productivity losses and product quality issues.

Workers not wanting to rotate because they have an “ easier job”.

Workers not wanting to change jobs to learn new work tasks for a variety of reasons.

Workers not wanting to give up “their job” to others.

Workers not qualified for some jobs due to restrictions or abilities.

Union or other workplace policies related to job bidding and compensation.

Supervisors are not convinced that the benefits are worth the perceived costs.

Supervisors perceive that implementation and management of job rotation is very difficult.

Group leaders and trainers tend to focus on the short-term costs rather than the long-term benefits, and perceive that the costs are too high for them verses the benefits.

Supervisors and group leaders not wanting to “fight” employees who don’t want to rotate.

PPE

Employers have duties concerning the provision and use of personal protective equipment (PPE) at work.

Health and Safety Risk Assessment

PPE will be identified as a Control Measure in the Risk Assessment and is Task Based.

Equipment

PPE is equipment that will protect the user against health or safety risks at work. It can include items such as:

Safety helmets

Gloves

Eye protection

High-visibility clothing

Safety footwear and safety harnesses

It also includes respiratory protective equipment (RPE).

Why is PPE important?

Making the workplace safe includes providing instructions, procedures, training and supervision to encourage people to work safely and responsibly. Even where engineering controls and safe systems of work have been applied, some hazards might remain. These include injuries to:

The lungs from breathing in contaminated air

The head and feet, for example from falling materials

The eyes, for example from flying particles or splashes of corrosive liquids

The skin, for example from contact with corrosive materials

The body, for example from extremes of heat or cold

PPE is needed in these cases to reduce the risk.

What do I have to do?

Only use PPE as a last resort

If PPE is still needed after implementing other controls, and there will be circumstances when it is, for example head protection on most construction sites, you must provide this for your employees free of charge.

You must choose the equipment carefully, see selection details below, and ensure employees are trained to use it properly, and know how to detect and report any faults.

Selection and use

You should ask yourself the following questions:

Who is exposed and to what?

How long are they exposed for?

How much are they exposed to?

When selecting and using PPE:

Choose products which are SABS marked in accordance with the Personal Protective Equipment Regulations - suppliers can advise you.

Choose equipment that suits the user - consider the size, fit and weight of the PPE. If the users help choose it, they will be more likely to use it.

If more than one item of PPE is worn at the same time, make sure they can be used together, for instance, wearing safety glasses may disturb the seal of a respirator, causing air leaks.

Instruct and train people how to use it, for example train people to remove gloves without contaminating their skin. Tell them why it is needed, when to use it and what its limitations are.

Nevel allow exemptions from wearing PPE for those jobs that only take a few minutes.

Check with your supplier on what PPE is appropriate - explain the job to them.

If in doubt, seek further advice from a specialist adviser.

Maintenance

PPE must be properly looked after and stored when not in use, for instance, in a dry, clean cupboard. If it is reusable it must be cleaned and kept in good condition.

Think about rules:

Using the right replacement parts which match the original, for example respirator filters.

Keeping replacement PPE available.

Who is responsible for maintenance and how it is to be done.

Having a supply of appropriate disposable suits which are useful for dirty jobs where laundry costs are high, for example for visitors who need protective clothing.

Employees must make proper use of PPE and report its loss or destruction or any fault in it.

Monitor and review

Check regularly that PPE is used. If it isn’t, find out why not.

Safety signs can be a useful reminder the PPE should be worn.

Take note of any changes in equipment, materials and methods - you may need to update what you provide.

Types of PPE you can use:

Body Part: Eyes

Hazard: Chemical or metal splash, dust, projectiles, gas and vapour, radiation

Options: Safety spectacles, goggles, face screens, face shields, visors

Make sure the eye protection chosen the right combination of impact, t/splash/molten/metal eye protection for the task and fits the user properly.

Body Part: Head and neck

Hazard: Impact from falling or flying objects, risk of head bumping, hair getting tangled in machinery, chemical drips or splash, climate or temperature

Options: Industrial safety helmets, bump caps, hairnets and firefighters’ helmets

Some safety helmets incorporate or can be fitted with specially-designed eye or hearing protection. Don’t forget neck protection, for example scarves for use during welding. Replace head protection if it is damaged.

Body Part: Ears

Hazard: Noise - a combination of sound level and duration of exposure, very high level sounds are a hazard even with short duration.

Options: Earplugs, earmuffs, semi insert / canal caps

Provide the right hearing protectors for the type of work, and make sure workers know how to fit them. Choose protectors that reduce noise to an acceptable level, while allowing for safety and communication.

Body Part: Hands and arms

Hazard: Abrasion, temperature extremes, cuts and punctures, impact, chemicals, electric shock, radiation, vibration, biological agents and prolonged immersion in water.

Options: Gloves, gloves with a cuff, gauntlets and sleeving that covers part or all of the arm

Avoid gloves when operating machines such as bench drills where the gloves might get caught. Some materials are quickly penetrated by chemicals, take care in selection. Barrier creams are unreliable and are no substitute for proper PPE. Wearing gloves for long periods can make the skin hot and sweaty, leading to skin problems. Using separate cotton inner gloves can help prevent this.

Body Part: Feet and legs

Hazard: Wet, hot and cold conditions, electrostatic build-up, slipping, cuts and punctures, falling objects, heavy loads, metal and chemical splash, vehicles.

Options: Safety boots and shoes with protective toe caps and penetration-resistant, mid-sole wellington boots and specific footwear, e.g. foundry shoes and chainsaw boots.

Footwear can have a variety of sole patterns and materials to help prevent slips in different conditions, including oil - or chemical-resistant soles. It can also be anti-static electrically conductive or thermally insulating. Appropriate footwear should be selected for the risks identified.

Body Part: Lungs

Hazard: Oxygen-deficient atmospheres, dust, gases and vapours

Option: Respiratory protective equipment (RPE). Some respirators rely on filtering contaminants from workplace air. These include simple filtering facepieces and respirators and power-assisted respirators. Make sure it fits properly, e.g. for tight-fitting respirators (filtering facepieces, half and full masks). There are also types of breathing apparatus which gives an independent supply of breathable air, e.g. fresh-air hose, compressed airline and self-contained breathing apparatus.

Filters have only a limited life. Where there is a shortage of oxygen or any danger of losing consciousness due to exposure to high levels of harmful fumes, only use breathing apparatus, never use a filtering cartridge. You will need to use breathing apparatus in a confined space or if there is a chance of an oxygen deficiency in the work area.

Body Part: Whole body

Hazard: Heat, chemical or metal splash, spray from pressure leaks or spray guns, contaminated dust, impact or penetration, excessive wear or entanglement of own clothing.

Options: Conventional or disposable overalls, boiler suits, aprons, chemical suits.

The choice of materials includes flame-retardant, anti-static, chain mail, chemically impermeable, and high-visibility. Don’t forget other protection , like safety harnesses or life jackets and emergency equipment. Careful selection, maintenance and realistic operator training is needed for equipment for use in emergencies, like compressed-air escape breathing apparatus, respirators and safety ropes or harnesses.

For all your Health and Safety needs, click on the picture below:

Posted date: 3rd May 2019

Latest News - Injuries on Duty (IODs) - Health-&-Safety-Services - General Health and Safety - Personal Protective Equipment (PPE) - Risk Assessment - OHS Risk Assessment

Comments (3)

Thank you Basil for sharing such insightful information 👏 👍 will certainly post on LinkedIn

2022-02-21 10:18:00Very informative!! Thank you very much Basil

2022-02-21 11:28:53This is awesome information Thank you very much Basil for sharing

2022-02-23 08:32:01